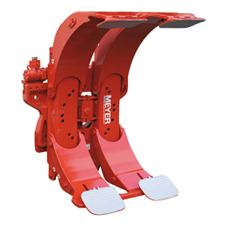

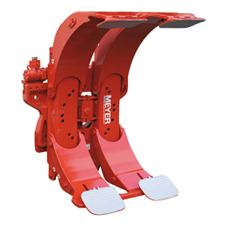

Models 5-22 / 5-26 33 G/G-A

| Single roll clamps - Unsplit long arm |

| 5-2233G-13A | 3500 | 650 | 250-1300 | 1020 | 905 | 281 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-13 | 3500 | 650 | 400-1300 | 1020 | 895 | 281 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-15A | 3300 | 760 | 250-1520 | 1020 | 945 | 305 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-15 | 3300 | 760 | 500-1520 | 1020 | 935 | 305 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-16A | 3200 | 800 | 250-1600 | 1020 | 955 | 315 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-16 | 3200 | 800 | 550-1600 | 1020 | 945 | 315 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-18A | 2800 | 915 | 250-1830 | 1020 | 1015 | 351 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2233G-18 | 2800 | 915 | 600-1830 | 1020 | 1005 | 351 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 1 - 2 roll clamps - Split long arm |

| 5-2633G-13A | 3500 | 650 | 250-1300 | 1020 | 890 | 273 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-13 | 3500 | 650 | 400-1300 | 1020 | 880 | 273 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-15A | 3300 | 760 | 250-1520 | 1020 | 930 | 297 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-15 | 3300 | 760 | 500-1520 | 1020 | 920 | 297 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-16A | 3200 | 800 | 250-1600 | 1020 | 940 | 307 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-16 | 3200 | 800 | 550-1600 | 1020 | 930 | 307 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-18A | 2800 | 915 | 250-1830 | 1020 | 1000 | 343 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

| 5-2633G-18 | 2800 | 915 | 600-1830 | 1020 | 990 | 343 | 335 | 217 | 240 x 400 | 200 | 190 | 3 / 4 A |

Notes:

- Two hydraulic functions required.

- Adjustable pressure relief valve is included.

- Short arm: adjustable at 45-degree rotation.

- Models 5-xxxx-xx with fixed (non-moving) short arm.

- Models 5-xxxx-xx-A with hydraulically positionable short arm.

- See hydraulic specifications page for pressure and flow rate recommendations.

- Standard contact pads: metal grain pattern with high-friction surface.

- Minimum 3,5-degree forward tilt on lift mast is required for horizontal handling.

Options:

- Special roll ranges.

- Models with “A” have a moveable short arm

- Contact pad options:

- - steel-sprayed

- - rubber faced

- - polyurethane faced.