FIND YOUR WEREHOUSE & LOGISTICS SOLUTIONS

FIND YOUR WEREHOUSE & LOGISTICS SOLUTIONS

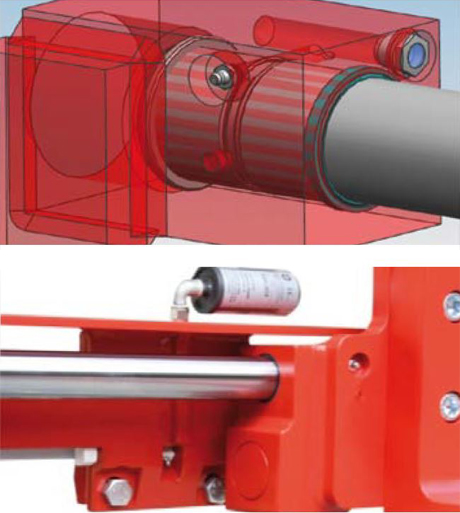

Automated Lubrication ensures synchronized truck and attachment maintenance intervals - no intermediate maintenance.

The Automated Lubrication System is an integral part of the encapsuled MEYER Shaft Guide Concept (Patent). Reduced maintenance requirements and life cycle costs.

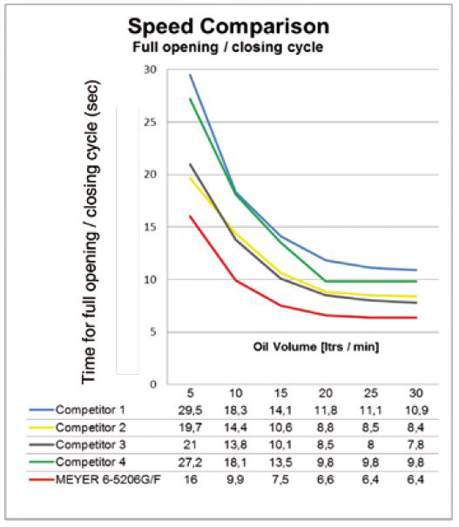

Influencing factor “Working Speed”:

The MEYER shaft-guided pallet handler achieves an up to 50% higher movement speed in operation.

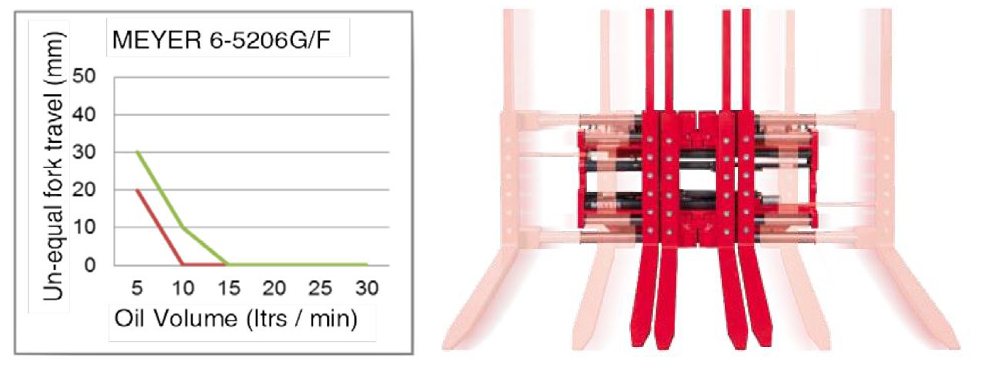

Effects and risks of un-equal fork travel:

The MEYER Shaft Guide Concept offers synchronized fork travel already at a very low oil flow: