AGV - Automated Guided Vehicles, are customized, fully-automated, driverless vehicles for

continuous 24/7 operation, capable of transporting pallets, boxes, reels and other

products throughout the warehouse and production plants.

Automated solutions applied to material handling world are continuously evolving.

Automated Guided Vehicles are included in this change and represent the new challenge for forklift truck and attachment manufacturers today. In strict cooperation with main AGVs producers, Bolzoni has developed a range of attachments equipped with specific sensors controlled and managed directly by the AGV control unit.

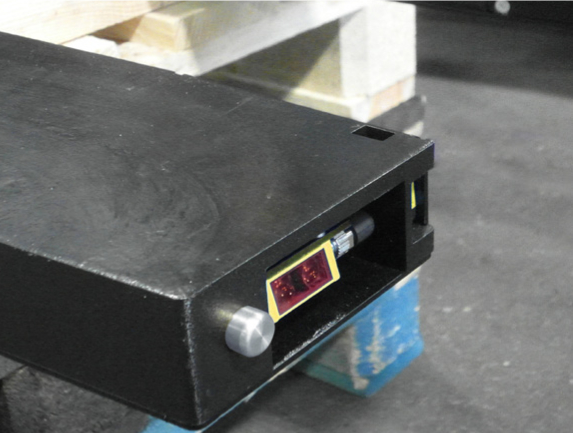

We focus on new technologies and we currently cooperate in developing, designing and manufacturing special handling attachments for AGV applications. Our products can be hydraulically as well as electrically operated. We can provide products equipped with full set of sensors, as per customer specifications, or with an agreed pre-setting to accept customer’s own sensors and cabling.

We use to closely cooperate with our customer Engineers in order to deliver the right product fit for purpose. Our range covers applications in the industries of paper, tobacco, food and beverage, automotive, home appliances, logistic and many others. We have developed as well a specific attachment for very narrow aisle applications.

The latest technology development in Bolzoni has been to design and manufacture fully electric driven attachments. The possibility to avoid any hydraulic has multiple benefits: cleaner environment, better and more efficient connection with the AGV control system, more precise, reliable and repetitive movement and correct positioning of the different attachment operations.

Bolzoni is investing heavily in electronic technology, using more and more sensors and cameras.

The 360-degree support includes the co-design and the installation.

Bolzoni has a dedicated Technical and Sales Team to support the AGV (automated guided vehicles) manufacturers. The implementation of each attachment is the result of a co-design between our customer’s and our project team. Following specifications and instructions on the electronics to be fitted on the attachment, we design, manufacture and deliver the attachment, which often integrates hydraulic, electronics, sensors and mechanic.

The attachment can be delivered as plug-and-play solution, meaning we take care of engineering, purchasing and manufacturing of all components. Furthermore delivery includes the parameterization of the attachment on the AGV lift truck.

We are strongly committed to providing our customers with high-quality service support before, during and after the purchase. When maintenance is required, our global service network is available, with well-equipped workshops, large spare parts storage and, above all, very skilled sales Engineers and a paramount after Sales Service.

We are always at hand, guaranteeing fast response times whatever the job or the situation. Rely on our After Sales, Field Service and Workshop Network offering you a localised 360-degree service support.

To offer the best tools for improving customer processes, AGV solution providers can rely on the cooperation with Bolzoni Auramo.

We can offer different level of solutions:

- Standard equipment with sensors and cabling pre-set

- Turn-key solutions with complete fitment of sensors and cabling

- Customized solutions in co-design with AGV producer

Bolzoni is one of the worldwide leading manufacturers of lift truck attachments, forks and lift tables. The company has manufacturing plants in Italy, Germany, Finland, America and China, and through its network of direct branches and independent dealers covering all continents it is able to satisfy all market requirements.

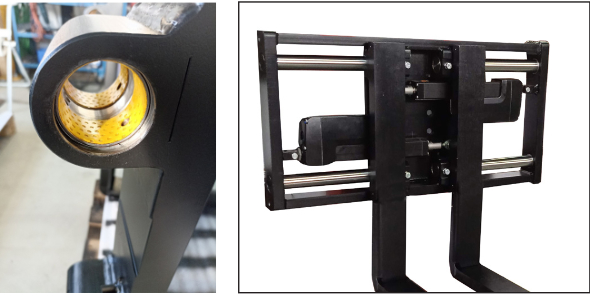

We are the only attachments manufacturer offering sliding arms and forks, both on sliding profile, with self-lubricating plastic inserts, or on shaft guide. The unique encapsulated shaft guide concept is a heavy-duty sliding system, which produces a very low friction, offering the fastest forks and arms mouvement, with high energy savings.

The sliding occurs on chromed bars fitted with a closed lubricating bushing system, not allowing any grease leakage. This system has been tested for over 25 years now on the market and has been very successful also because of the very low maintenance requirements.

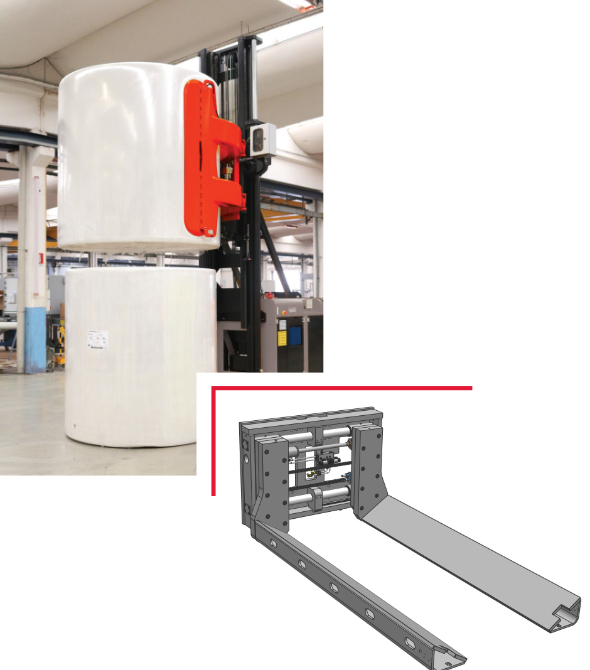

In paper world, specifically in tissue paper production facilities, significant heavy machines and important clamping force, necessary to handle big rolls, steer the technical decision to more traditional hydraulic solutions. A worldwide leader in tissue production and distribution for one of the biggest tissue paper plants in North America, decided to manage transportation and warehousing of parent rolls (more than 5 tons of weight and 3m of diameter) with heavy LGVs equipped with Bolzoni dedicated clamps. The hydraulic system and the sensors set have been co-designed with the LGV manufacturer and specifically adjusted to match the demands set by the control system of the automatic machine.

Additionally, the Bolzoni paper roll clamp range includes specific models dedicated to the horizontal handling of rolls.

The Bolzoni roll clamp range includes both 360- and 180-degree rotating roll clamps, as well as non-rotating clamps. If rotation is required, for the AGV applications we recommend the 180-degree solution, whose smaller hydraulic circuit allows for a faster and precise handling. Moreover, this type of rotation has the advantage of having the cable passage paced through the rotator, with a consequent reduction in the attachment thickness, HCG and weight.

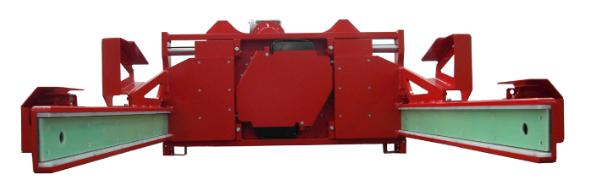

When an important AGV producer had to face the mission for a worldwide tobacco producer to clamp, stack and empty by rotating bins of tobacco, they decided to cooperate with Bolzoni and to co-design fully electric driven 360-degree rotating box clamps . It is proven that the electric driven rotating device can do the work in a much better, clean and easy way.

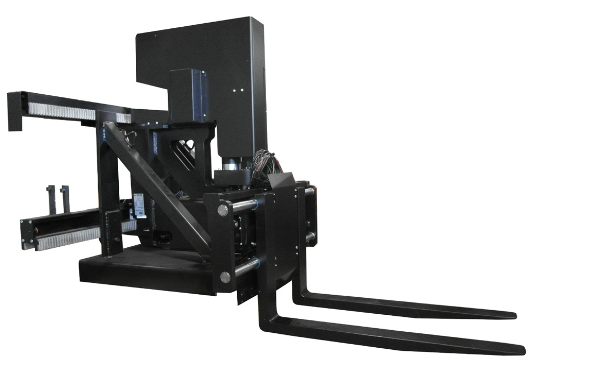

One of the worldwide leading producers in food & beverage industry uses narrow aisle AGVs equipped with electric driven Bolzoni trilateral heads. Beyond the possibility to avoid hydraulic fluid in the handling equipment, the AGV manufacturer has been able to better control the unit, allowing complete 180-degree rotation of the head inside the aisle, great advantage to increase the speed of the operation, and the productivity of the warehousing system. Hydraulic driven trilateral version available.

When the AGV needs to position the forks for different pallet sizes, it can use a Bolzoni electric driven fork positioners, operated by electric actuators, easy to control and more precise in positioning. As well, in collaboration with another world leader in AGV and automatic solution provider, Bolzoni developed fully electric fork positioners for the automotive industry. The units, thanks to electric actuator, are able to precisely position the forks depending on the load to carry. A full set of sensors installed on the attachments help the AGV to exploit the different missions and to fulfil all handling needs in the manufacturing and warehousing processes.

Main sensors applied on AGV Forks:

Besides listed sensors, we are fully available to customize both forks and sensors, according to your specific needs.